Engineering Services

Our team of metallurgical experts can provide support for all your consulting and problem-solving needs.

The staff, equipment, and machine shop all contribute to our excellence in providing a full-service metallurgical test lab. Whether high volume examinations for steel mills or grain size examinations of Inconel foil, our team can perform all examinations. The following is a list of our metallographic services and capabilities

Examinations

- Grain Size Exam – ASTM E112

- Heat Treatment Evaluation

- Case Depth Measurement

- Phase Determination by Image Analysis

- Graphite Microstructure Exam – ASTM A247

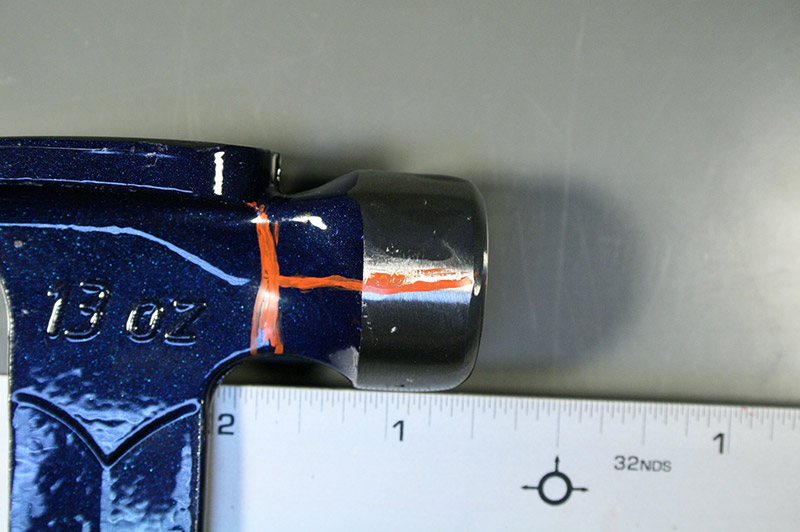

- Discontinuity Identification and Verification

- Decarburization Exam – ASTM E10778, SAE J121 and J419<

- Inclusion Rating – ASTM E45, ISO 4697, DIN 50602 and JIS G 0555

Contact us today to learn more about our engineering services.

Expert Metal Testing Lab

Clemex Technologies provides image analysis systems and image analysis software for quality control and research laboratories.

SGS MSi has two microscopes outfitted with Clemex image analysis software systems, one with a motorized stage that permits automatic E45 exams for up to 12 samples to be evaluated at one time. The metallurgical department also has two Clemex stereomicroscope systems and a brand new Clemex microhardness system that permits detailed surveys to be stored and repeated. Clemex equipment is specifically designed for material evaluation. That is why our examinations at SGS MSi are performed faster, are more reliable and the photographs are clearer and with have more image analysis options. The background of our staff with steel mill metallurgy has made SGS MSi nationally recognized for our excellence in metallurgy, microstructure exams and failure analysis services. We have even been involved with solving complex microstructural defect situations that have been traced all the way back to the original melt shop practices. Nationally recognized authorities from the metallurgical community have confirmed and support our findings.

The facility and equipment supporting our team is the latest available from the metallurgical testing industry. Plating thickness examinations, ASTM and ISO microcleanliness examinations, grain size exams, phase percentages and mosaic metallography are performed by our Clemex Image analysis software system. The system performs ASTM E45 exams on up to six samples at once – providing complete heat verification in accordance with E45 microcleanliness specification requirements. The microscope calibration is traceable to NIST and provides all dimensions directly on screen for easy understanding of photographs by our clients. The mosaic capability allows multiple low magnification views to be “stitched together” by the software to permit complete views of weld profiles or entire crack lengths that could previously only be photographed using macrophotography techniques. Our clients have all provided tremendous positive feedback on the photographs provided by the Clemex Image Software and superior wide field optics of the Epiphot microscope.

Our team understands that aside from on-time delivery of test results the actual report must be clear, concise and easy to understand. Metallographic exam results are explained with photographs and labels directly in the photographs. Arrows identifying specific features or artifacts in photographs help educate our clients and their customers. Answering specific questions in test reports have helped to resolve client dispute situations and provide closure to claims. The metallurgical testing experience of our team is known for our straightforward approach to problem-solving which is supported by our world-class facility and staff. Give a try and see the difference for yourself.