Industries Served

We analyze metals and alloys using precise destructive methods to determine their chemical, mechanical, and metallurgical characteristics

An A2LA and ISO/IEC 17025 accredited laboratory, we analyze metals and alloys using precise destructive methods to determine their chemical, mechanical, and metallurgical characteristics. These test results help additive manufacturers determine whether a material meets their application’s safety, performance, functional and durability requirements. Our full suite of services include:

- Raw material validation

- Production issue solutions

- Finished and semi-finished good assessment

- Product failure analysis

- High-end metallurgical engineering services

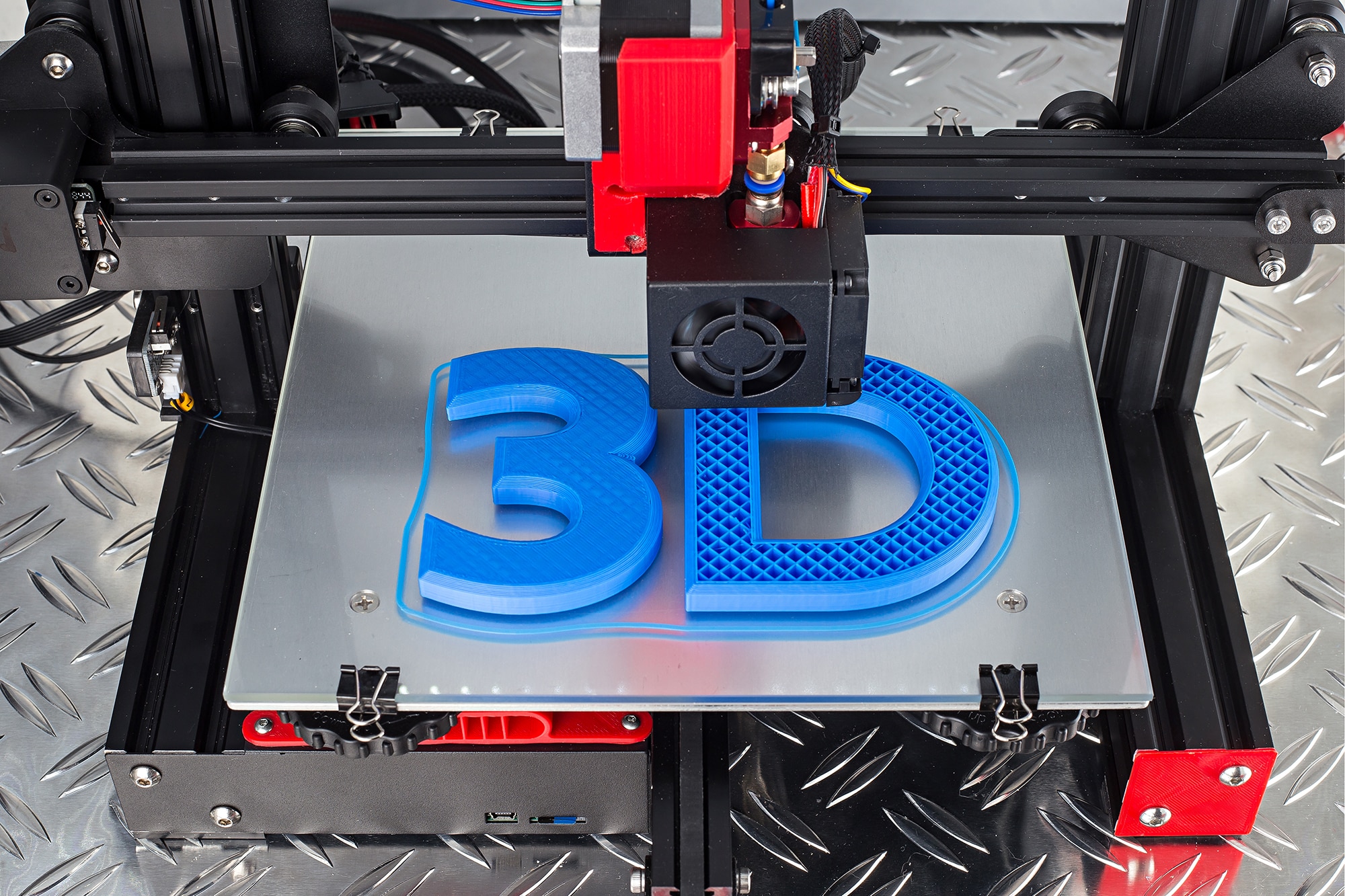

With more than three decades of experience working with materials utilized for 3D printing applications, our team of skilled technicians and chemists is well positioned to examine and validate your specimens. Common tests we perform for this industry include:

We can examine and certify specimens to nearly any industry standard or customer-specific requirement, but materials used in the additive manufacturing industry are often tested against Metal Powder Industries Federation Standard 35. This specification helps guide designers and materials engineers with additive manufacturing processes, including the metal 3D printing process.

Our metallurgists can analyze a wide array of materials destined for use by 3D printers. Examples include:

- Powdered metals

- Sintered metals

At SGS MSi, we approach each job with a solutions-oriented mindset. The equipment at our laboratory in Melrose Park, IL is calibrated regularly to ensure accuracy. Calibration records are available upon request.

We provide a detailed report listing test type, parameters, and results obtained when analyzing materials. The language we use is clear and easy to understand. All engineering reports are presented with a summary conclusion of our findings, any criterion supporting those results and, if appropriate, insights into possible failure avoidance.

Make sure the materials you use are suitable for their intended purpose with reliable analyzing and certifying services from SGS MSi. With an unwavering commitment to quality, we’re your materials testing provider.

Contact us to learn more about our additive manufacturing testing and engineering services.

Test Methods and Specifications

The following is a listing of specifications that are in accordance with our A2LA and ISO accreditation.

- ASTM B311: Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

- ASTM B962: Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle

- ASTM B963: Standard Test Methods for Oil Content, Oil-Impregnation Efficiency, and Surface-Connected Porosity of Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle