Materials Tested

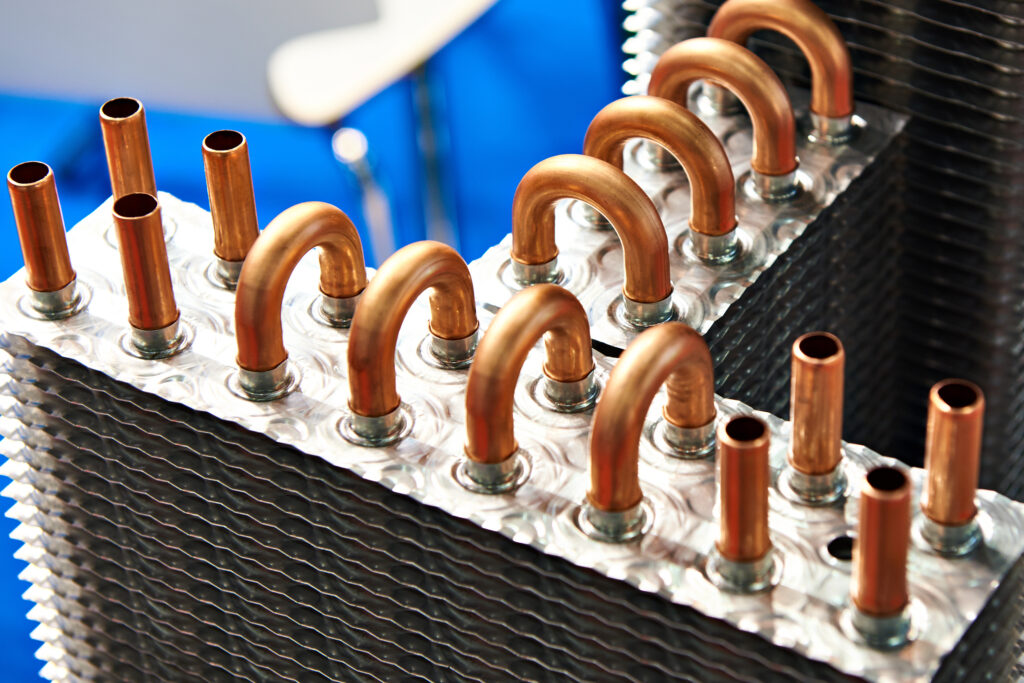

A superior conductor of electricity and heat, copper is a commonly alloyed metal known for its corrosion resistance, toughness, and ductility

At SGS MSi, our experienced team of engineers and chemists provides full-service chemical and metallurgical analysis for copper base alloys and other metals. Determining chemical composition and understanding alloy characteristics is a cost-effective way to verify material quality and performance.

Known for their versatility, copper base alloys have a wide range of uses, from plumbing to electronics. Common applications include:

- Propellers

- Plumbing fixtures

- Power lines

- High conductivity wiring

- Spark plugs

- Cooking utensils

Copper Alloy Testing Services

When combined with the right metals, copper provides superior wear resistance, durability and corrosion resistance. Throughout chemical testing, it is SGS MSi’s goal to provide customers with an accurate, detailed composition of your copper base alloy. Our team also certifies materials to applicable ASTM and industry standards.

Specializing in brass, bronze and other copper alloys, SGS MSi provides the following chemical analyses and procedures:

- Optical Emission Spectroscopy

- Inductively Coupled Plasma Mass Spectrometry

- Leco Analysis

- Alloy Identification & Verification

- X-ray Fluorescence

- Microwave Digestion

- Re-melt Capability

- Positive Material Identification Testing

Selecting the chemical analyses options that fit your project and budget, our reputable metallurgical laboratory also performs corrosion testing, safety testing and metal failure testing for most alloys and metals. SGS MSi serves the manufacturing, power generation, forging, foundry and medical industries, and our chemists provide detailed, easy-to-understand reports of all findings and recommendations.

Known for our customer-driven attitude, SGS MSi’s 33,000 square foot metallurgical testing facility utilizes air tubes, barcode scanning and airport display technology to track your copper alloy sample.

Contact us today to learn more about our metallurgical testing services.