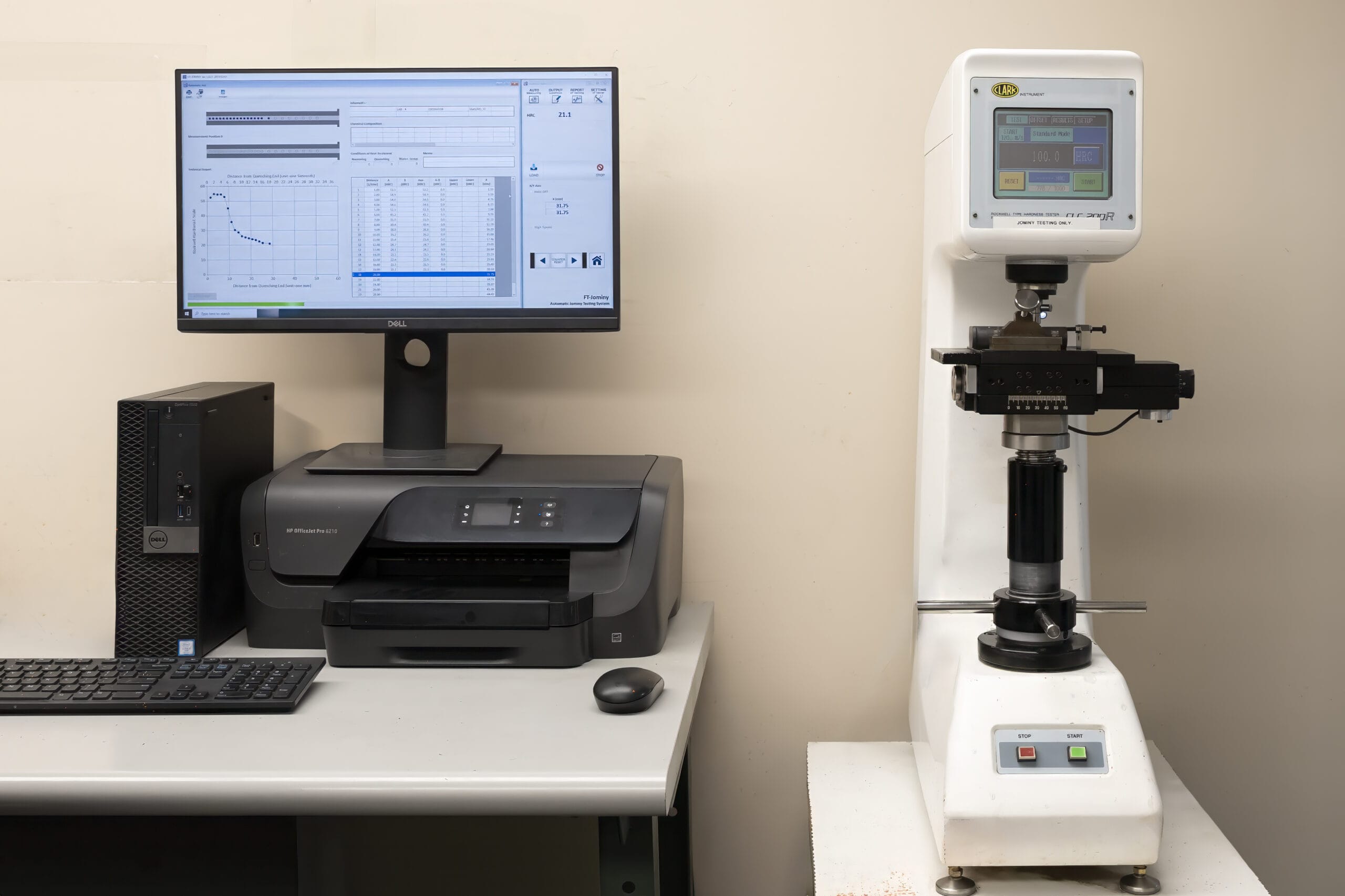

Hardness Testing

ASTM E18 Rockwell Testing from SGS MSi

Our testing schedule supports two shifts of personnel to ensure your material is processed on time.

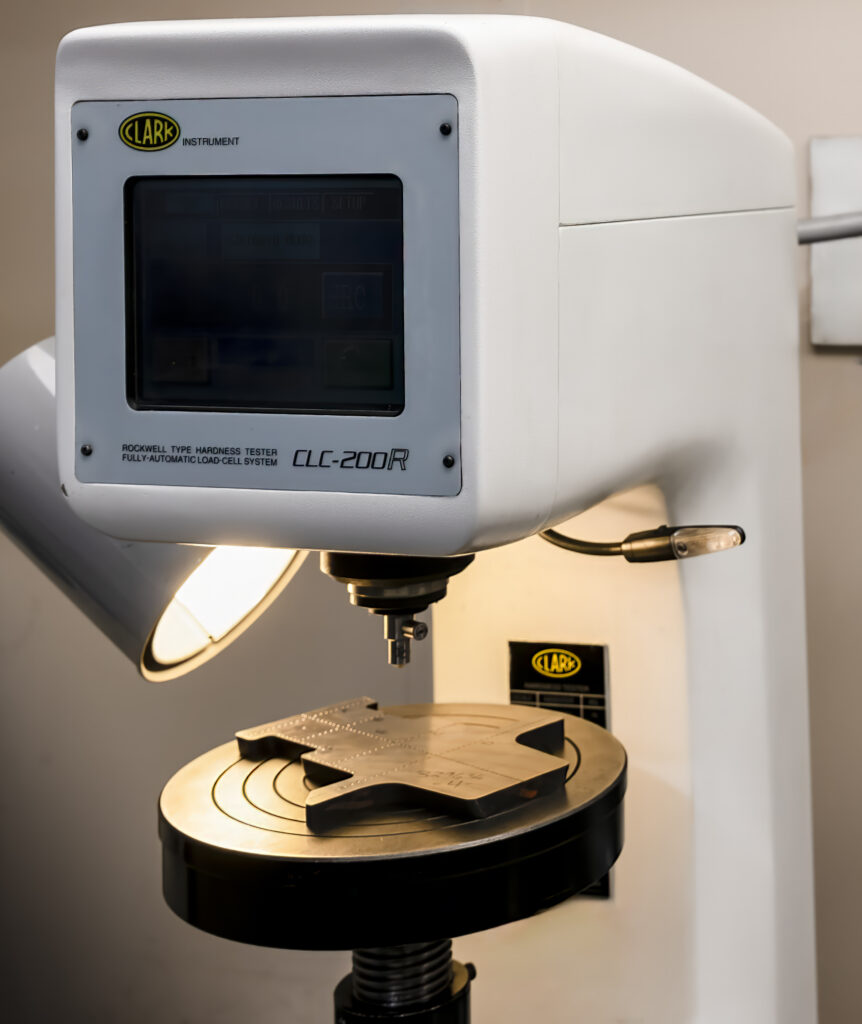

ASTM E18 Rockwell hardness testing employs both standard Rockwell and superficial test scales to accommodate all shapes and thicknesses of material for testing.

Once hardness values have been identified our engineers can convert the hardness values to other hardness scales in accordance with ASTM E140 and ASTM A370. These hardness values are approximate as identified within the specifications and are commonly used when Rockwell hardness tests are required to be converted to ASTM E10 Brinell hardness test values.

SGS MSi is accredited for the following Rockwell hardness scales:

- Rockwell A

Cemented carbides, thin steel and shallow case hardened steel - Rockwell B

Copper alloys, soft steels, aluminum alloys, malleable irons, etc. - Rockwell C

Steel, hard cast irons, case hardened steel and other materials harder than 100 HRB - Rockwell N – Diamond indenter

Thin materials, lightly carburized steel surfaces, or parts that might bend or crush - Rockwell T – 1/16” diameter steel ball indenter

Thin materials, lightly carburized steel surfaces

Engineers review all material and required specifications to ensure your hardness testing is being performed to the correct parameters

The sample preparation is the most critical part of the hardness test. If the test surfaces are not parallel, of sufficient thickness, or not wide enough to permit testing away from an edge, an erroneous test value will result.

Our engineers review all test results before release to our clients. Verifying the performed tests were performed correctly, display the proper relationship to other requested tests and did they meet the requested specification requirements.

Remember all of the hardness testers will always give you a test value, but it is our experience that allows us to review the results to be sure the test was performed correctly.

Contact us today to learn more about our hardness testing services.