Metallurgical Services

Macroetching, also known as deep etching, involves etching specimens prepared with a suitable acid or reagent for macrostructural examination.

This is done at low magnifications and rating by a graded series of photographs showing the incidence of certain conditions such as: cracks, pipe, center voids, center unsoundness, pinholes, porosity, white band, chill structure, dendritic structure, inclusions, hydrogen flakes, segregation, banding, grain size, mold slag, and other discontinuities or defects such as laps and seams.

Applications

- Development of grain flow in a forged part or fastener, which is a critical property for the integrity of the forging.

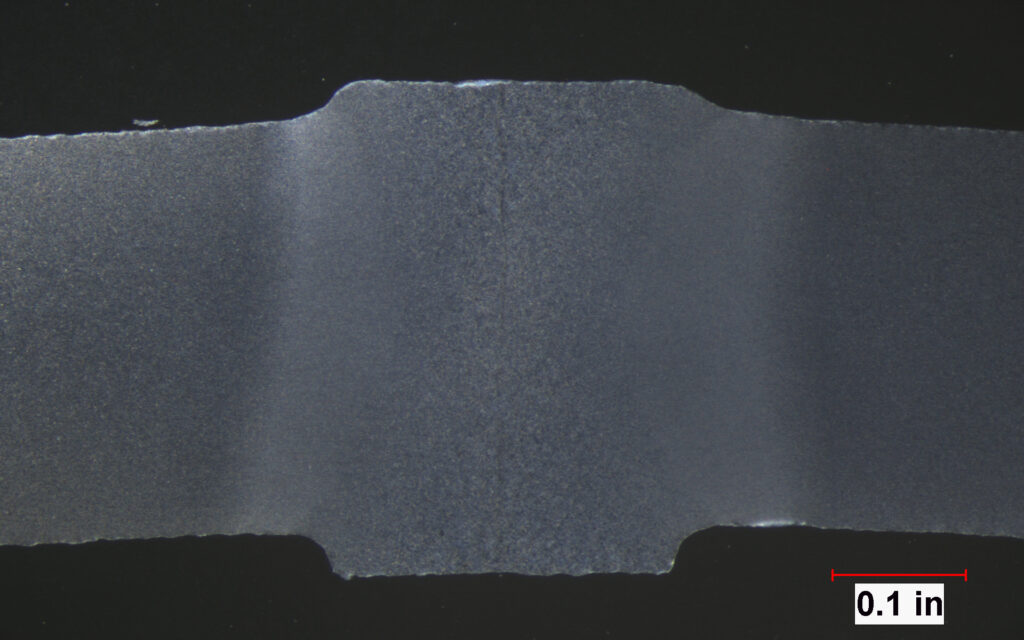

- Study of weld structures, definition of weld penetration, dilution of filler metal by base metals, entrapment of flux, porosity, and cracks in weld and heat affect zones, etc.

- Evaluation of heat treated parts to determine locations of hard or soft spots, tong marks, quench cracks, case depth in induction hardened or carburized parts, and effectiveness of stop-off coatings.

- Evaluation of machined parts for grinding cracks in tools and dies.

The most common reagent for macroetching iron and steel is a 1:1 mixture, by volume, of concentrate hydrochloric acid and water. Other reagents included: sulphuric acid, ammonium persulfate, and nitric acid.

Macroetching Examination Specifications

- ASTM E381: Standard Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

- ASTM E340: Standard Test Method for Macroetching Metals and Alloys

Acid Etch Testing

A form of destructive weld testing, acid etch exams are used to evaluate weld characteristics, analyze metal failure, and determine weld integrity. An expert in metallurgical testing and failure analysis, MSi Testing performs acid etch tests on a full range of corrosion-resistant metals and alloys. We proudly serve the needs of the automotive, construction, aerospace, food & beverage, manufacturing and other industries, and our team of chemists performs all acid etch exams to meet your project and budget objectives.

Acid Macroetch Testing

Used to test weld and metal quality and performance, acid macroetch testing can reveal the presence and degree of surface conditions and imperfections, including:

- Porosity

- Cracks

- Alloy segregation

- Thermal flaking

- Seams

- Presence of foreign materials\

- Poor fusion

In addition to acid etch testing, SGS MSi’s team of degreed engineers uses state-of-the-art equipment to perform other metallurgical and chemical analyses. Test types include:

- OES Spectroscopy

- ICP Metal Analysis

- XRF Analysis

- LECO Analysis (carbon, sulfur, oxygen, nitrogen, hydrogen)

- Microwave Digestion

- Alloy Verification & Identification

- Positive Material Identification Testing

- Re-melt Capability

Depending upon your sample size and usage requirements, MSi metal experts recommend the tests that achieve your goals—affordably and accurately. When your acid etch exam is complete, you will receive a detailed assessment of macroetch results and further recommendations. For your convenience, we boast the industry’s leading turnaround times—including same-day options for some tests and metallurgical procedures.

Contact us today to learn more about our metallurgical services.