SEM Analysis

Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Spectroscopy (EDX).

SEM EDX is the most recognized and widely used surface analysis technique that enables us to identify the following:

- Fatigue

- Intergranular Fractures

- Overload

- Hydrogen Embrittlement

- Wear

- Cavitation

- Ductile & Brittle Fractures

- Intergranular Corrosion

- Stress Corrosion

- Crevice Corrosion

- Galvanic Corrosion

- Pitting Corrosion

- Marine Corrosion

- Erosion

At SGS Ludwig we have state-of-the-art SEM. Our Hitachi SU3900 is capable of high magnification images, secondary images in backscatter with the enhanced UVD detector and image processing. The specimen chamber is one of the largest and can hold a 5” tall x 12” wide sample. The in-chamber camera allows for an ease in analysis and navigation of one part or multiple samples during an evaluation.

SEM is a scanning electron microscope capable of producing images of an object as small as 1nm. The electron beam interacts with the sample surface creating various signals of secondary electrons, backscattered electrons and x-rays. These signals are combined in a vacuum chamber to produce cathodoluminescence (CL), a high-resolution image up to 10,000x magnification. Our variable pressure / environmental capabilities allow us to perform SEM analyses and evaluations on non-conductive specimen and parts.

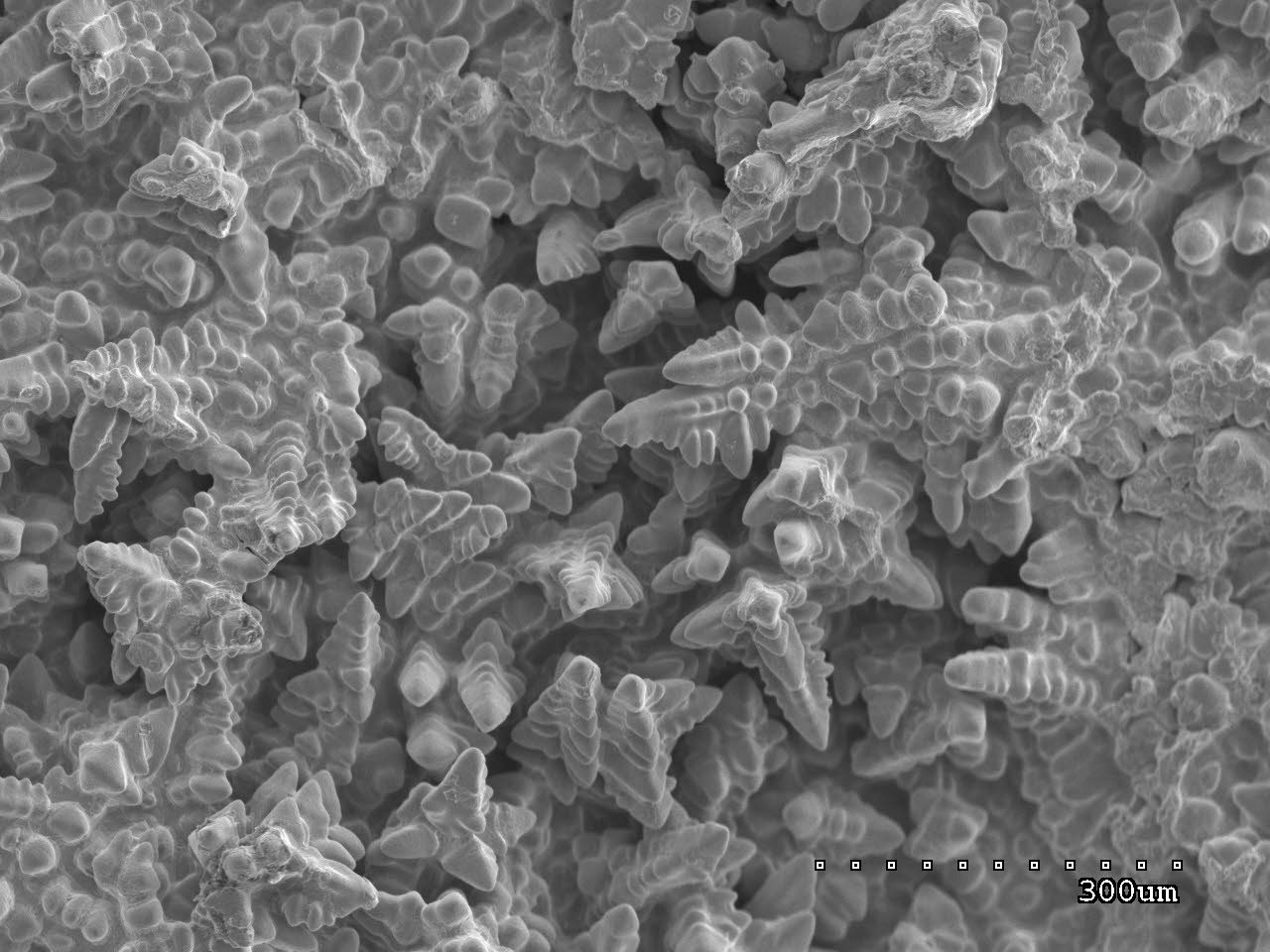

SEM analysis is utilized for particle characterization, such as wear debris generated during mechanical wear testing. The high magnification, high-resolution imaging of our SEM analysis supports the determination of the number, size, and morphology of small particles, allowing clients to understand the wear properties of their material. Using the microscope’s EDX analysis equipment, elemental compositions of individual particles can be determined.

Fractography is a component failure analysis that identifies crack growth and fracture characteristics of metals, components, and engineering structures. Fractography may be used to categorize failures into fatigue, cleavage, and dimple rupture, to name a few fracture modes.