Failure Analysis

Our accredited failure analysis laboratory offers you state-of-the-art instrumentation and a full-service machine shop

Our professional engineers with various industrial backgrounds are supported by a large 33,000 square foot facility including a 10,000 square foot machine shop, a microscopy laboratory with image analysis microscopes, OES, ICP and LECO equipped chemistry laboratory and SEM/EDS analysis. Our laboratories carry A2LA and ISO 17025 accreditations.

Our facility is staffed by ~50 full-time employees on two shifts. Our size and diversity allows us to also perform high volume routine metallurgical testing in addition to specialized failure analysis projects.

Specific areas of specialty are:

- Corrosion Failure Analysis

- Metal Failure Analysis

- Pipeline Failure Analysis

- Wellhead Component Failure Analysis

- Welding Failure Analysis

- Fastener Failure Analysis

- Heat Exchanger Failure Analysis

- Fossil & Nuclear Power Plant Experience

- Investigation Services

Contact us today to learn more about our failure analysis services.

We believe in thoughtful reporting practices – you’ll get test reports with rapid and accurate results, that are straightforward and easily read

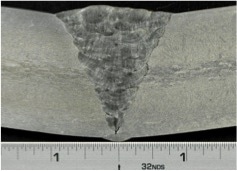

Our failure analysis test reports are documented with photographs that chronicle each step of the project as well as all critical evidence that supports the root cause conclusions. We are known for providing concise statements concerning the cause of the failure and what also was not found. It is important to answer the questions that your client’s customer is asking. This can put closure to the back and forth dialogue of the root cause. We also offer video conference capability to review the report draft, ensure all background is accurate, all your questions are answered and you accept the final product. These conferences allow all members of the project to provide input and correspondence. Our goal is to provide a complete and accurate analysis of your material with a clear and concise conclusion. Our engineering staff will help you toward investigative resolution on your failure analysis.