Materials Tested

Materials Tested

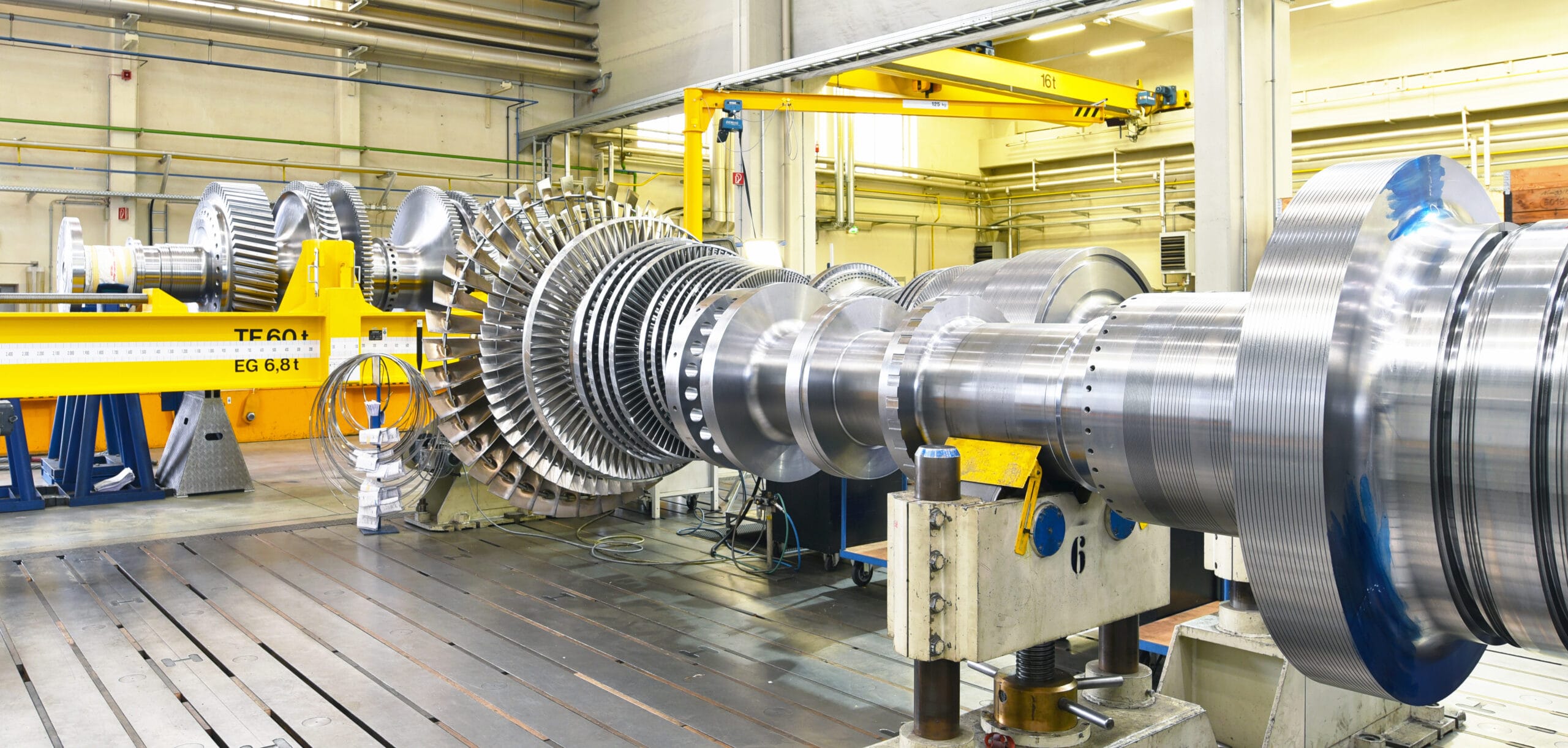

Our laboratory provides metal chemical analysis and testing services on a variety of materials. For more than 30 years our metallurgical experts have been working across nearly every industry to determining elemental composition and verification on a range of metallurgical materials.

SGS MSi has the capability to prepare and test all your materials for their elemental composition and alloy verification

Using multiple methods alone or in conjunction with one another provides a full analysis. Each analysis is certified to known standards and reviewed by an engineer if requested. Our equipment is calibrated for each material prior to testing and processed in a fast concise report.

Metal Analysis Testing Services

The following is a listing of chemical analysis capabilities available for your metallic material:

- OES – Optical Emission Spectrometry

- This method is for solid samples with a flat area of 1/2” and at least .010” thick

- ICP – Inductively Coupled Plasma

- This method is used for drillings, shavings and small samples. It utilizes a “wet chemistry” process where the sample is dissolved into solution and analyzed for its composition. 10 – 25 grams is needed for this process

- LECO – Combustion Analysis

- This method is used to analyze certain gases and elements such as Carbon, Sulphur, Hydrogen, Oxygen and Nitrogen. 3-5 grams is needed for this process

- XRF – X-ray Fluorescence

- Many times we receive samples of unknown origin or that require a sorting analysis. XRF can tell us what category the material is from, and allow for sorting or further chemical analysis. This test is semi-quantitative and cannot provide a full spectrum elemental composition. Another method can be added to provide material certification.

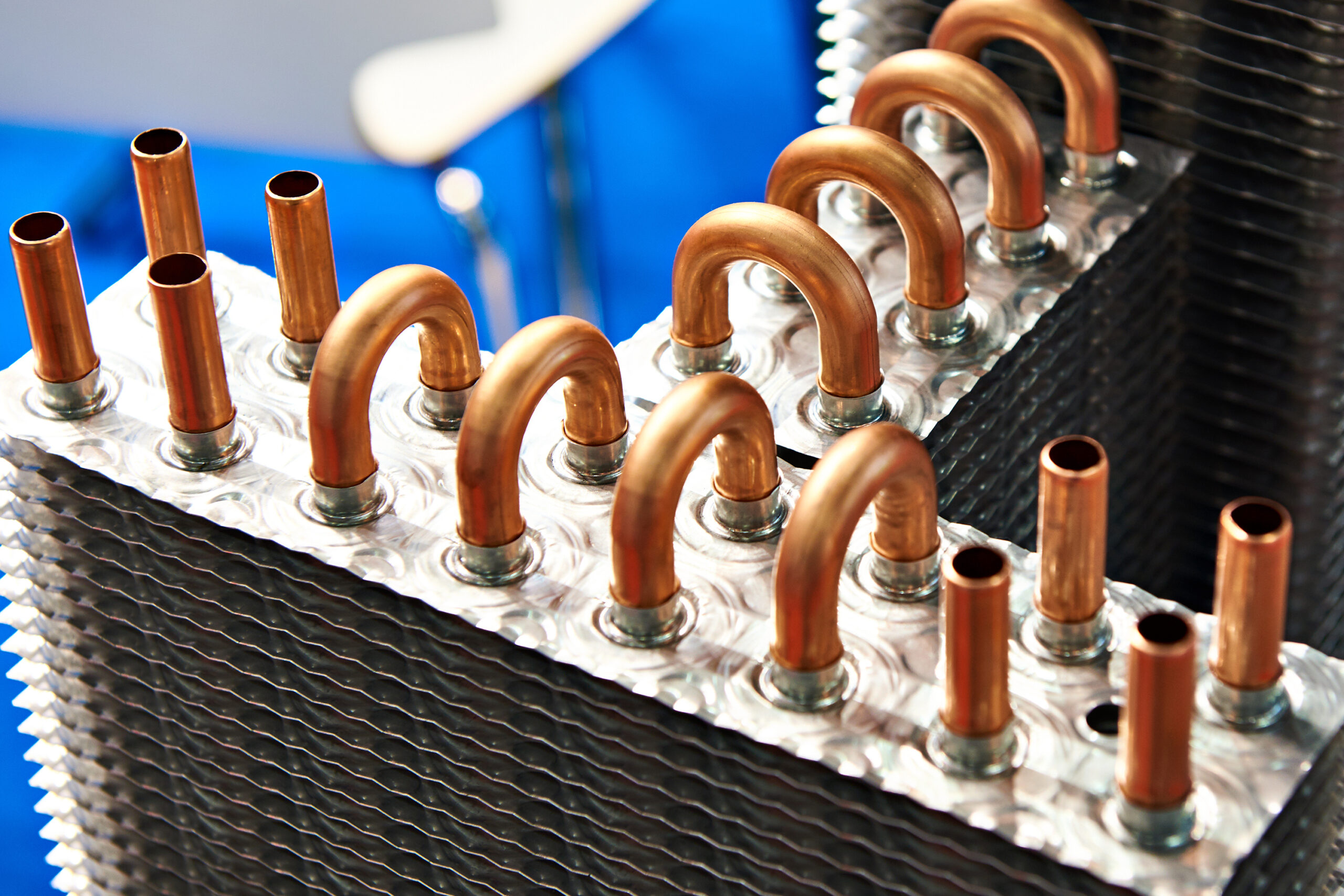

Flattening

SGS MSi has the capability to remelt small samples (excluding copper). Typically 50 grams are necessary to obtain a sizable button sample. Flattening of samples is also available to achieve a desired surface area sufficient to perform testing on tube or thin solid material.

We have the ability to flatten and re-melt samples to facilitate their compositional analysis. Contact us for more information on our metal testing services.