Mechanical Testing

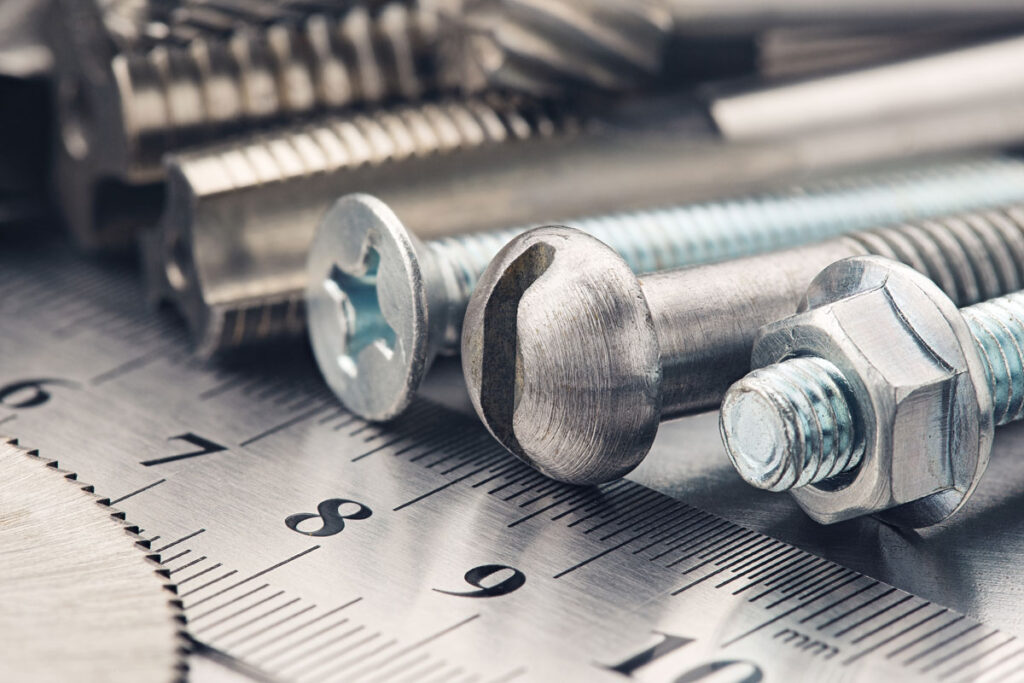

Fastener testing from SGS MSi – determine the mechanical properties of externally and internally threaded fasteners, washers, direct tension indicators, and rivets.

Testing may consist of a machined specimen or a full-size product. The type of fastener testing that will be described below applies to a full-size product testing. Fastener testing is not applicable to all. The head design, shank thickness, and product length can determine if the testing is required of the product. Contact us today to learn more about our mechanical testing services.

Axial Tensile

An Axial tensile test is a method for determining behavior of materials under axial tensile loading. The tests are conducted by fixturing the fastener into the test apparatus and then applying a force to the fastener by separating the testing machine crossheads.

Wedge Tensile

A Wedge tensile test is an axial test, except that a wedge is placed under the head during the testing. This wedge tensile test is typically done on hex or square head fastener and socket head cap screws. This test is to see if the head of the fastener is capable of sustaining the added stress of the wedge.

Proof Load

A proof load test consists of stressing the product with a specified load that the product must withstand without measurable permanent set (Method 1: Length Measurement).

Test Methods

The following is a listing of specifications that are in accordance with our A2LA and ISO accreditation and are some of the most common specifications we perform:

| ASTM F606/F606M | Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets | |

| ISO 898-1 | Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread | |

| SAE J429 | Mechanical and Quality Requirements For Externally Threaded Fasteners | |

| SAE J995 | Mechanical and Material Requirements for Steel Nuts | |

| SAE J1199 | Mechanical and Material Requirements for Metric Externally Threaded Steel Fasteners(STABILIZED Feb 2013) |