Hardness Testing

Hardness testing from SGS MSi

Our metallurgical laboratory carries A2LA and ISO 17025 accreditations. We are equipped with the latest hardness testing equipment and have decades of experience with ASTM methods and additional hardness testing requirements.

Microhardness Testing

Our accredited laboratory uses Vickers hardness test and Knoop hardness test equipment image analysis technology for automatic impression reading. The Clemex microhardness system can perform a microhardness test in any location on a specimen and then automatically read the impression size calibrated and traceable to NIST standards. Whether a Vickers test or Knoop testing the Clemex system has both indenters on an automated turret that can let the operator quickly switch between projects. MSi also has two manual Vickers testing and Knoop microhardness testing machines that can double the capacity of the hardness test lab for larger projects.

SGS MSi staff of laboratory technicians are supervised by a department manager who provides training and helps department scheduling. Vickers hardness testing or Knoop hardness testing projects to ASTM E384 requirements can require multiple technicians to complete the project on time. The use of the automatic Clemex system allows a technician to set up a Knoop microhardness test and while the specimen is running the technician can also performing another hardness test in another part of the metallurgical laboratory.

Additional Testing Methods

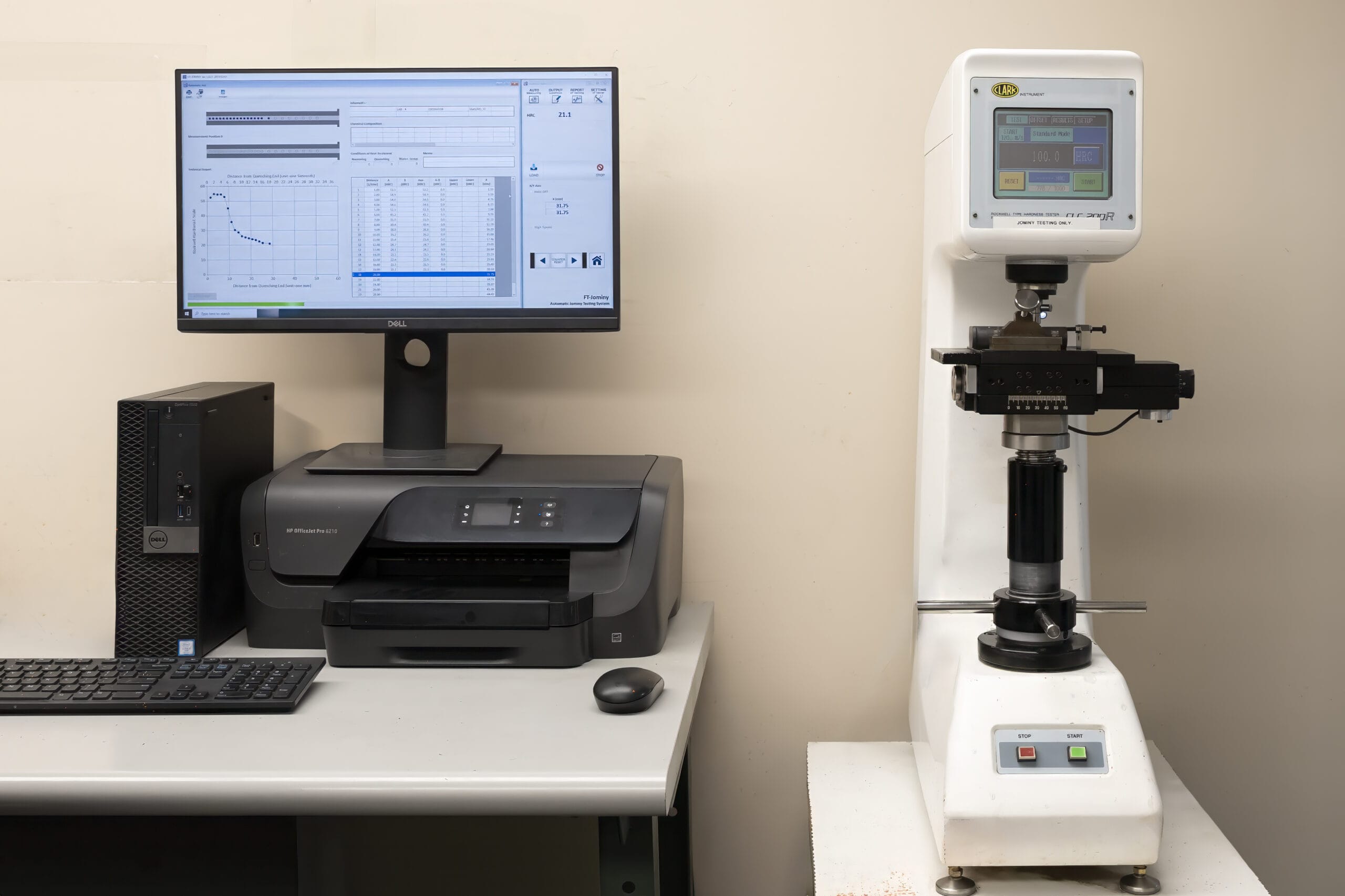

Besides microhardness testing MSi has automated Rockwell Hardness Testing and Brinell Hardness Testing capabilities. SGS MSi also has Macro-Vickers Hardness Testing capabilities for hardness testing of weld cross-sections. Macro-Vickers testing employs a 10 kg. test load that is typically requested on projects for components that are for export to Europe or Canada. Multiple types of hardness tests can be used when performing a metallurgical failure analysis depending on the component and the industry. SGS MSi has the capabilities to run all required tests to solve the problem or meet the project requirements.

Whether Rockwell, macro-Vickers or microhardness testing, sample preparation is critical to the success of the test project. All microhardness testing is performed on metallographic specimens that must be sectioned without altering the material that is being tested. This is no easy task when high hardness samples can be easily tempered (burnt) by incorrect or aggressive abrasive cutting techniques. SGS MSi has multiple types of abrasive cutting equipment including a low stress, automatic feed diamond wafer cut-off saw to insure that the specimen is unaffected by the sample preparation.

Contact us today to learn more about our hardness testing services.