Mechanical Testing

Weld Testing Services from SGS MSi

Whether a weld procedure qualification test or welder qualification testing, SGS MSi has a 10,000 square foot machine shop fully equipped to handle any size weld coupon.

Our Services

Pipe Weld Testing

Using the most innovative techniques to ensure weld performance over a material’s lifetime, our pipe weld tests include destructive methods such as macro etch testing, fillet break tests, bend tests, electromagnetic tests, and x-ray methods.

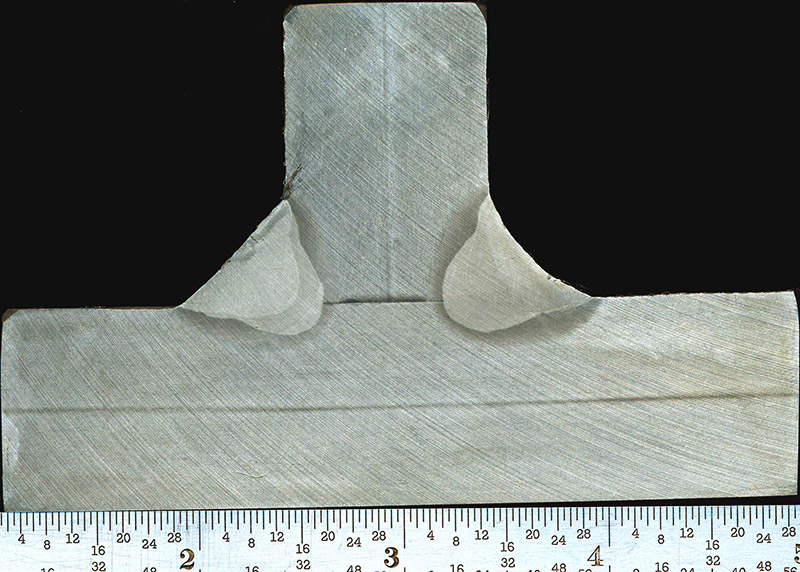

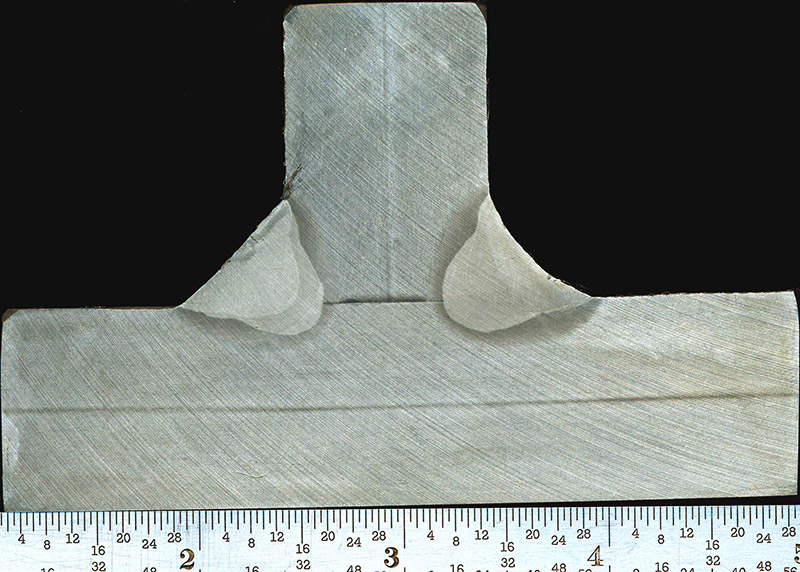

Fillet Weld Testing

Specializing in weld testing for a range of industries, SGS MSi provides fillet weld testing that determines the quality of any welded joint. Over the course of a weld’s lifetime, it encounters intense loads and fatigue.

Structural Weld Testing

A leader in weld testing and weld quality services, SGS MSi uses destructive procedures to assess the quality and performance of metal and alloy welds.

Weld Penetration

A common weld defect, incomplete penetration creates crevices that impact a weld’s integrity and longevity. When corrosive substances seep into crevices, materials are prone to damage —and may lead to defects that impact safety and performance.

CWI Testing

SGS MSi’s CWI services consist of tests that help establish welding procedures, procedure qualifications and welder qualifications.

Additional testing services:

- Weld Bend Testing

- AWS B4.0 Weld Testing

- Welding Failure Analysis

- Welding Qualification

- Welding Certification Testing

- Weld Procedure Qualification

- ASME Section IX Weld Testingx

Weld Test Machine Shop

Our machine shop has eight band saws with the ability to section all sizes of weld coupons. We have sectioned a 28” diameter, 3” thick wall, type 304 stainless steel piping coupon for a nuclear application. Once sectioned, we have three CNC turning centers, three CNC milling centers and three 3-axis surface grinders to machine bend tests, Tensile tests or Charpy Impact tests. Having multiple pieces of machining equipment ensures rapid test turn-around in critical situations.

When a weld test requires outside inspection, the testing process is much more critical, involving extremely tight scheduling and attention to details. It is this type of critical testing where our services are recognized as superior to other metal testing laboratories. Having a full second shift for our machine shop and mechanical testing lab allows us to complete testing in less than half the time of other laboratories.

Contact us today to learn more about our mechanical testing services.