Metallurgical Services

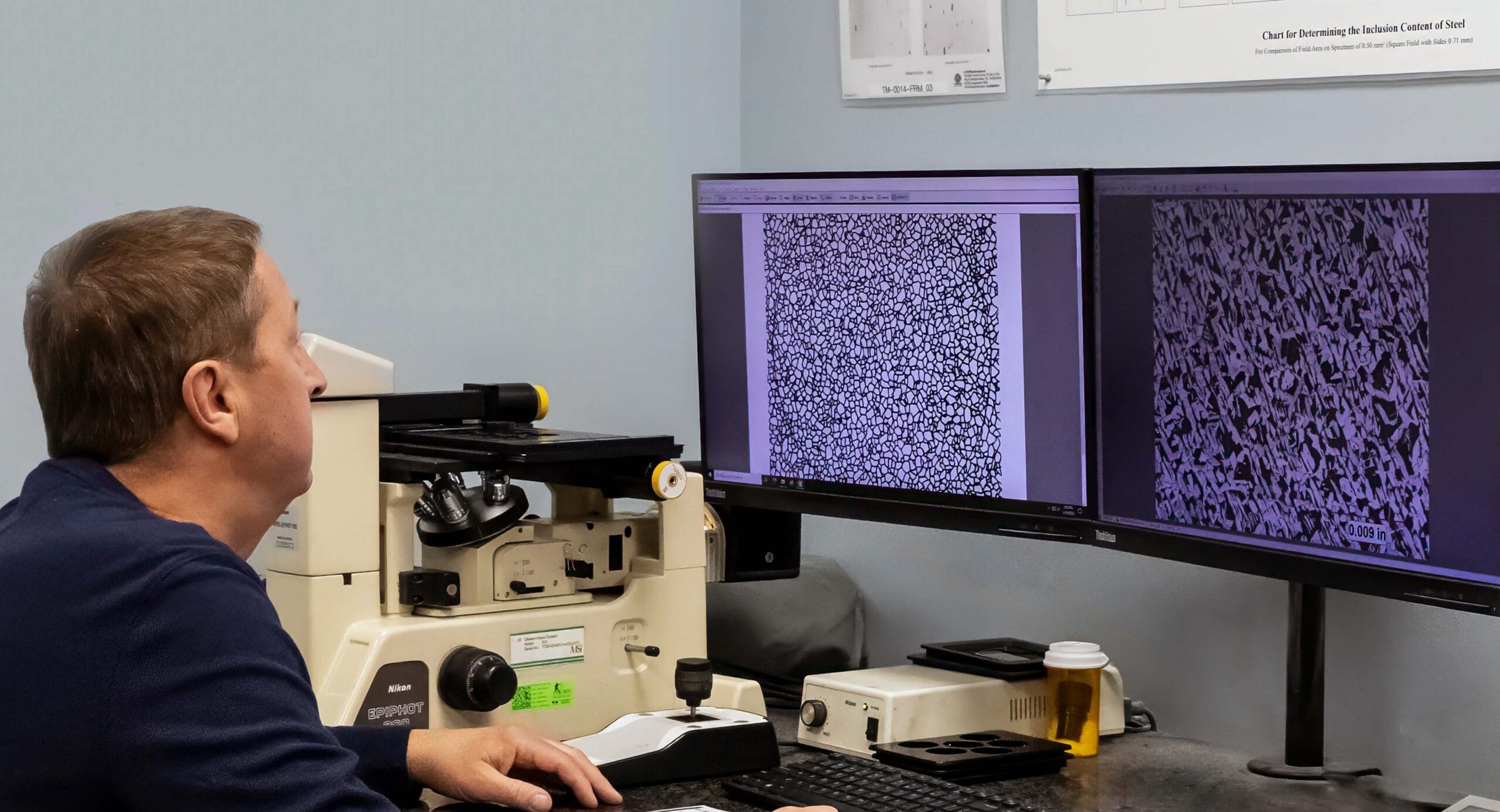

Decarburization Testing Laboratory

When heat treating steel at temperatures that are around the austenite eutectoid temperature (1292°F – 1492°F), a phenomenon known as “decarburization” can occur. If the heat treating environment is rich with oxygen or hydrogen, carbon can diffuse from the steel’s surface and react with these elements. As carbon decreases on the surface, a layer of ferrite forms. Decarburization can be intentional and controlled, but it is often undesirable in the steelmaking process as the low-hardness surface ferrite layer can result in, for example, reduced strength, reduced fatigue resistance, reduced wear resistance, and increased rate of crack growth.

We can test for decarburization at our laboratory using ASTM E1077 and SAE J419 as our accredited test specifications. There are three general types of decarburization that we are able to characterize in ferrous materials:

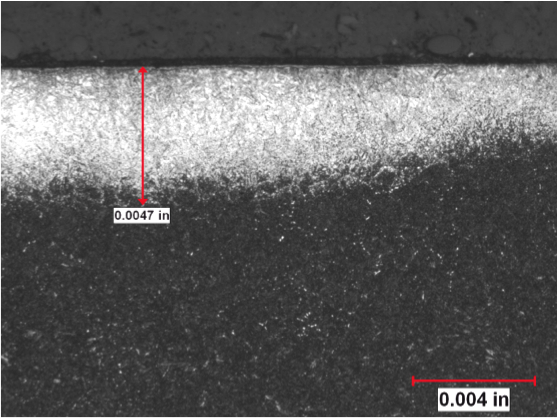

- Type 1 Decarburization

A measurable layer of carbon-free ferrite is present at the surface in this condition (known as “complete decarburization”, or 100% loss of carbon). - Type 2 Decarburization*

More than 50% of the carbon is lost on the surface, but no measurable depth of complete decarburization is present in this condition. - Type 3 Decarburization*

Less than 50% of the carbon is lost on the surface, and no measurable depth of complete decarburization is present in this condition.

*Type 2 and Type 3 are known as Partial Decarburization.

Contact us today to learn more about our metallurgical testing services.

Test Methods and Specifications

The following is a listing of specifications that are in accordance with our A2LA and ISO accreditation.

- ASTM E1077

- SAE J121

- SAE J419