Metallurgical Services

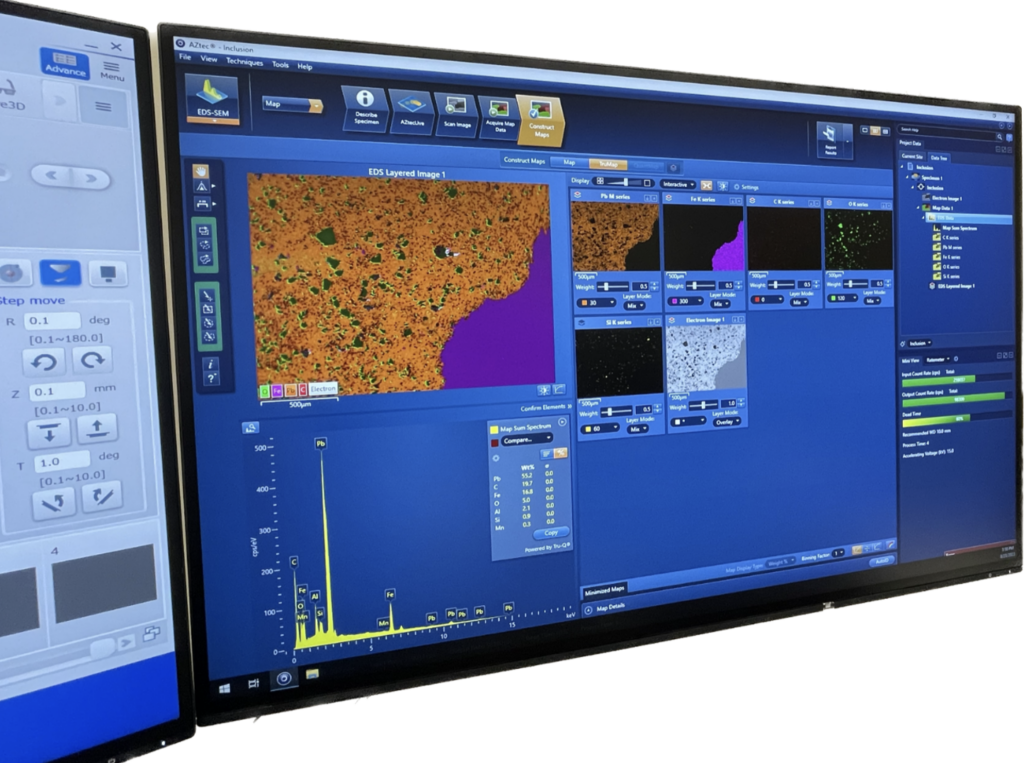

SGS MSi is a metallurgical expert in Energy Dispersive Spectrometry

Energy Dispersive Spectroscopy (EDS) is a type of elemental analysis used to characterize the chemical composition of a material while observing it microscopically in our SEM. We can perform EDS on most metallic samples to identify these characteristics.

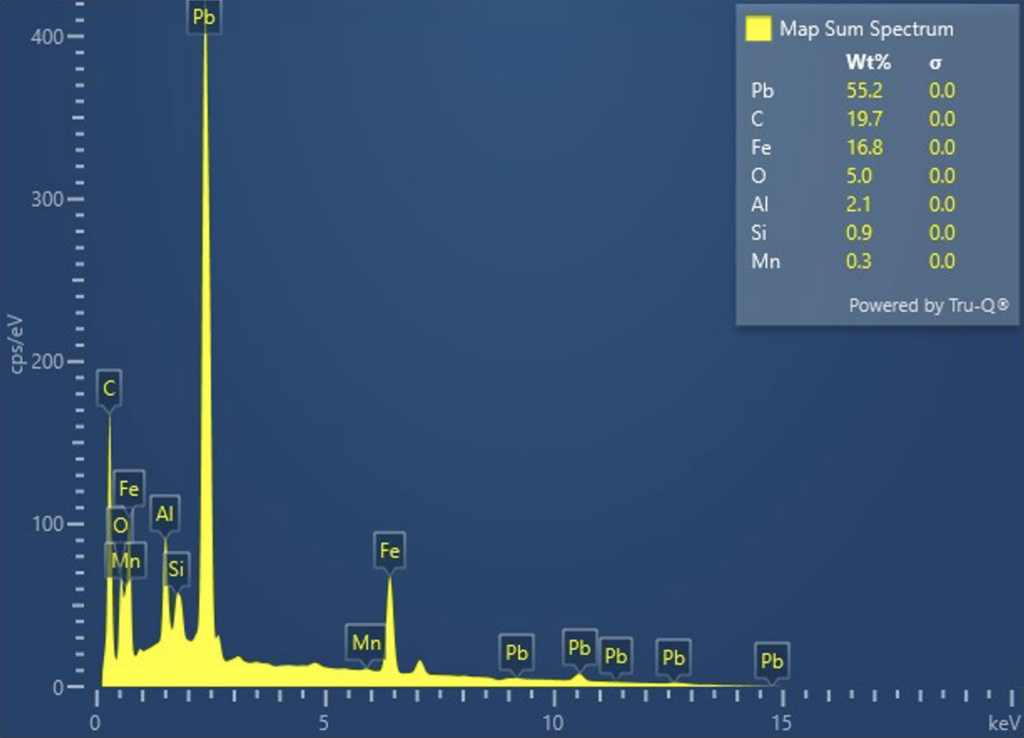

Our expertise in EDS can provide a semi-quantitative elemental analysis of the material. EDS can be used to determine which chemical elements are present in a sample, and can be used to estimate their relative abundance. EDS also helps to measure multi-layer coating thickness of metallic coatings and analysis of various alloys. The accuracy of this analysis of a sample composition is affected by various factors, hence we use this method for qualitative purposes.

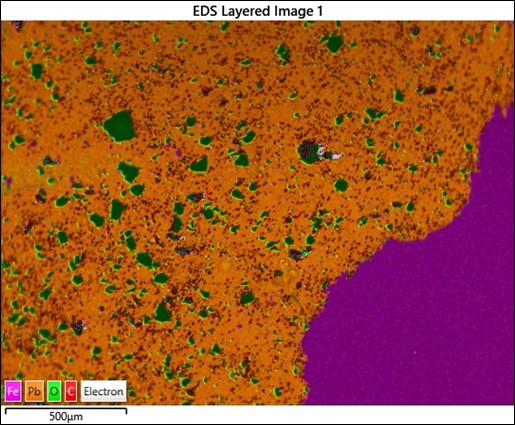

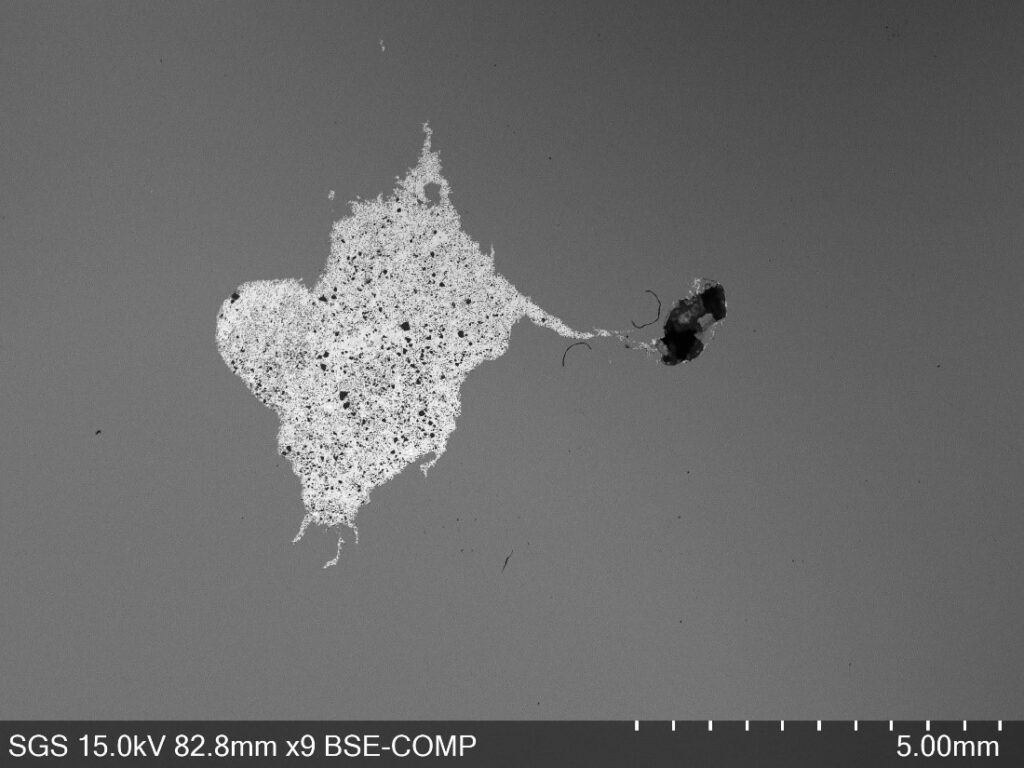

For example, EDS analysis is particularly useful when an inclusion, contamination or a discontinuity is found in a sample. Our engineers scan the surface of the material to identify these discontinuities and determine its elemental make-up. With our mapping technologies we can supply an elemental map of the inclusion or contamination to understand the source of the issue. These indications can help determine a failure mode or inconsistency of a material.

Contact us today to learn more about our metallurgical services.

EDS Test Methods & Specifications

The following is a listing of specifications that are in accordance with our A2LA and ISO accreditation.