Metallurgical Services

There are a number of microscopic test methods that have been developed to determine the non-metallic inclusion content rating of wrought steel.

For each method, inclusions are assigned to a category based on similarities in morphology, and not necessarily on their chemical identity. These test methods deal only with recommended test methods and should not be construed as defining or establishing limits of acceptability for any grade of steel.

The most common microscopic inclusion ratings performed for steel in the US are ASTM E45 Methods A and E, also referred as JK inclusion rating. These methods place inclusions into one of several composition-related categories (Type A – Sulfides, Type B – Aluminates, Type C – Silicates, Type D – Globular Oxides). These types of inclusions are referred to as “indigenous inclusions”. The microscopic methods are not intended for assessing the content of “exogenous inclusions” (those from entrapped slag or refractories). Microanalytical techniques such as energy dispersive X-ray spectroscopy (EDS) may be used to aid in determining the nature of the inclusion.

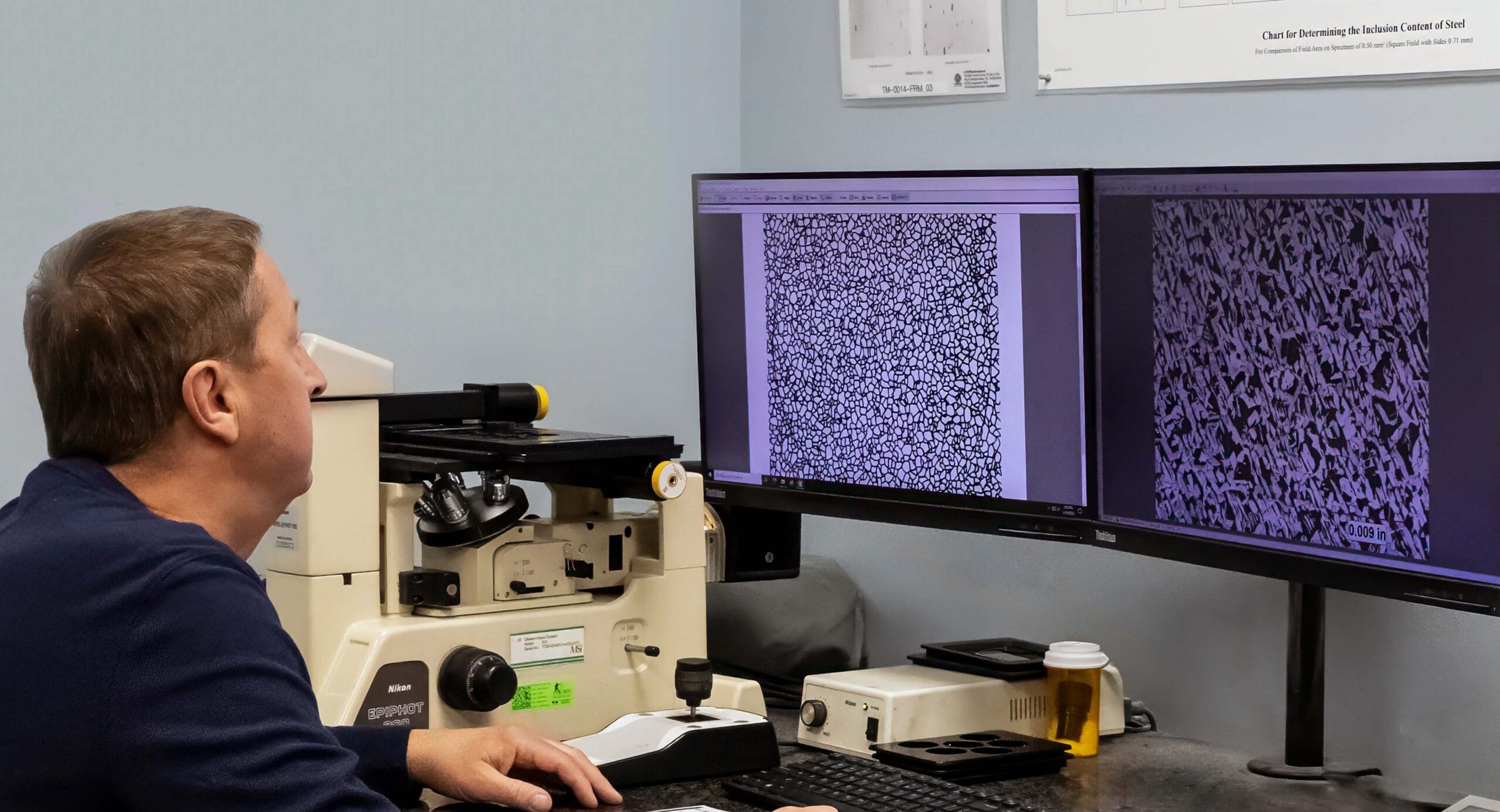

Materials with very low inclusion contents may be more accurately rated by automatic image analysis, which permits more precise microscopic ratings. We employ an automated image analysis system by Clemex Technologies, which provides standardized programming that conforms to many of the following specifications.

Inclusion Rating Test Methods

Contact us today to learn more about our metallurgical testing services.

| ASTM E45 | Methods A, C, D, E: Standard Test Methods for Determining the Inclusion Content of Steel | |

| ASTM E1245 | Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis | |

| SAE AMS 2315 | Free Ferrite Content Method For Determining Percent | |

| ASTM E3 | Standard Guide for Preparation of Metallographic Specimens | |

| SAE J422 | Microscopic Determination of Inclusions in Steels(STABILIZED Jan 2018) | |

| ISO 4967 | Steel — Determination of content of non-metallic inclusions — Micrographic method using standard diagrams | |

| DIN 50602 | Metallographic examination; microscopic examination of special steels using standard diagrams to assess the content of non-metallic inclusions | |

| JIS G 0555 | Microscopic testing method for the non-metallic inclusions in steel | |

| AMS 2301 | Aircraft Quality Steel Cleanliness Magnetic Particle Inspection Procedure | |

| AMS 2304 | Special Aircraft – Quality Steel Cleanliness Magnetic Particle Inspection Procedure |