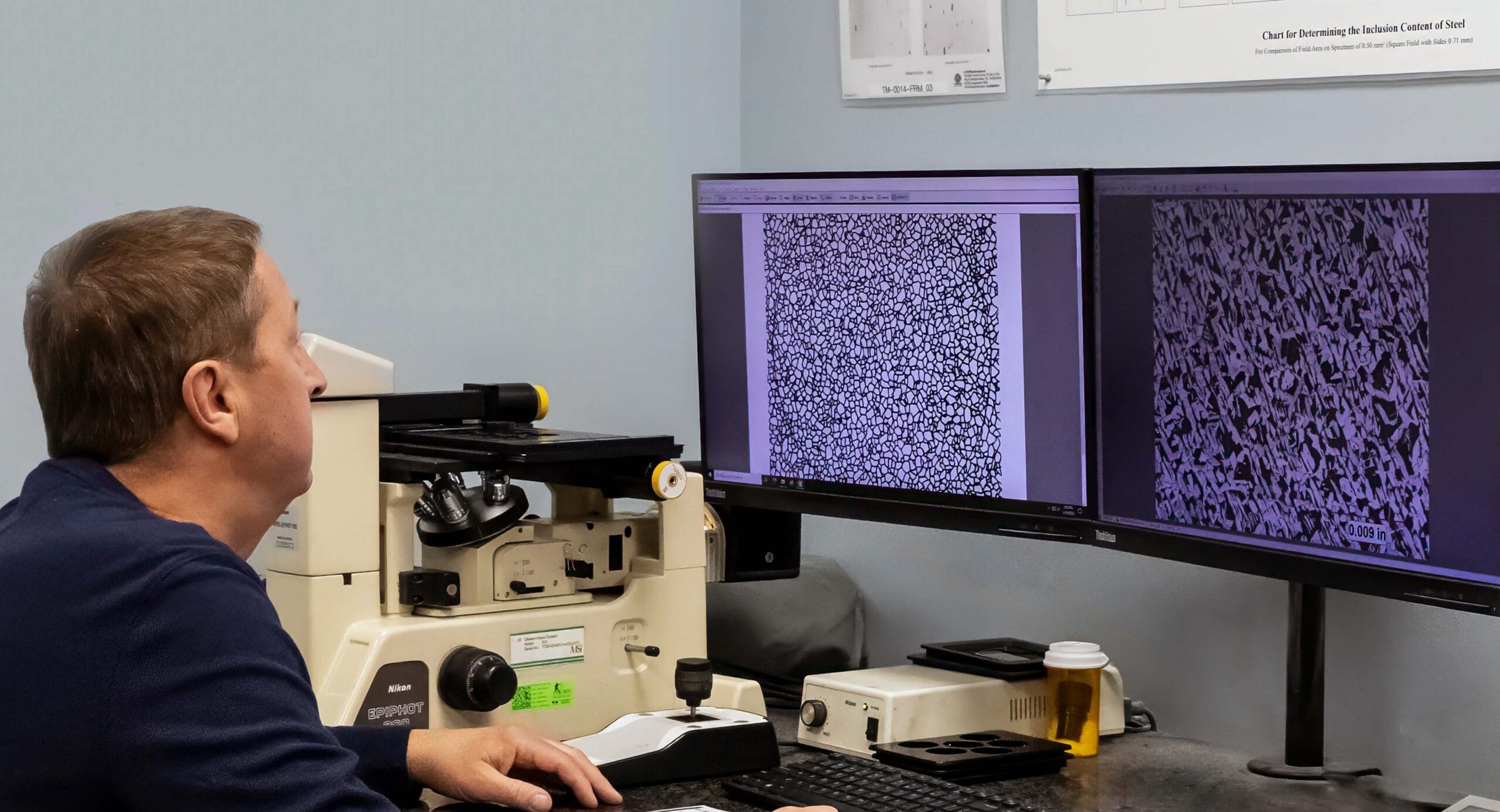

Metallurgical Services

Frequency severity testing is a macro cleanliness examination that counts the number and length of macro inclusions identified during fluorescent magnetic particle inspection.

Cleaner steel is more valuable as it can be applied to higher rotating stress applications. Rotating parts typically fail via fatigue initiating from non-metallic inclusions. Consequently, the frequency severity test is a standard test for the validation of material intended for automotive applications.

Frequency Severity Testing

The testing is typically performed at the mill or service center level for macro-cleanliness rating of bars or billets. An entire heat can be evaluated when the examinations is performed on a minimum of six billets prior to rolling. The billets are subcontracted to an open die forger where the rolling process is simulated by forging to a minimum 4:1 reduction of the billet.

Actual rolled bars can also be evaluated, but each individual size must then be tested. Again a minimum of six bars per size/heat must be evaluated to qualify the entire heat at the given diameter.

SGS MSi has a close relationship with an open die forger that permits rapid turn-around of test samples to meet critical delivery requirements. Our technicians are trained on two shifts to provide rapid machining and examinations after forging. SGS MSi is a leader in frequency severity examinations to over multiple different mills.

Test Methods

Contact us today to learn more about our metallurgical testing.

| SAE AMS2300 | Premium Aircraft Quality Steel Cleanliness Magnetic Particle Inspection Procedure | |

| SAE AMS2301 | Aircraft Quality Steel Cleanliness Magnetic Particle Inspection Procedure | |

| SAE AMS2303 | Aircraft Quality Steel Cleanliness Martensitic Corrosion Resistant Steels Magnetic Particle Inspection Procedure | |

| SAE AMS2304 | Special Aircraft Quality Steel Cleanliness Magnetic Particle Inspection Procedure | |

| JIS G 0556 | Method of macro-streak-flaw test for steel |