Reverse Engineering

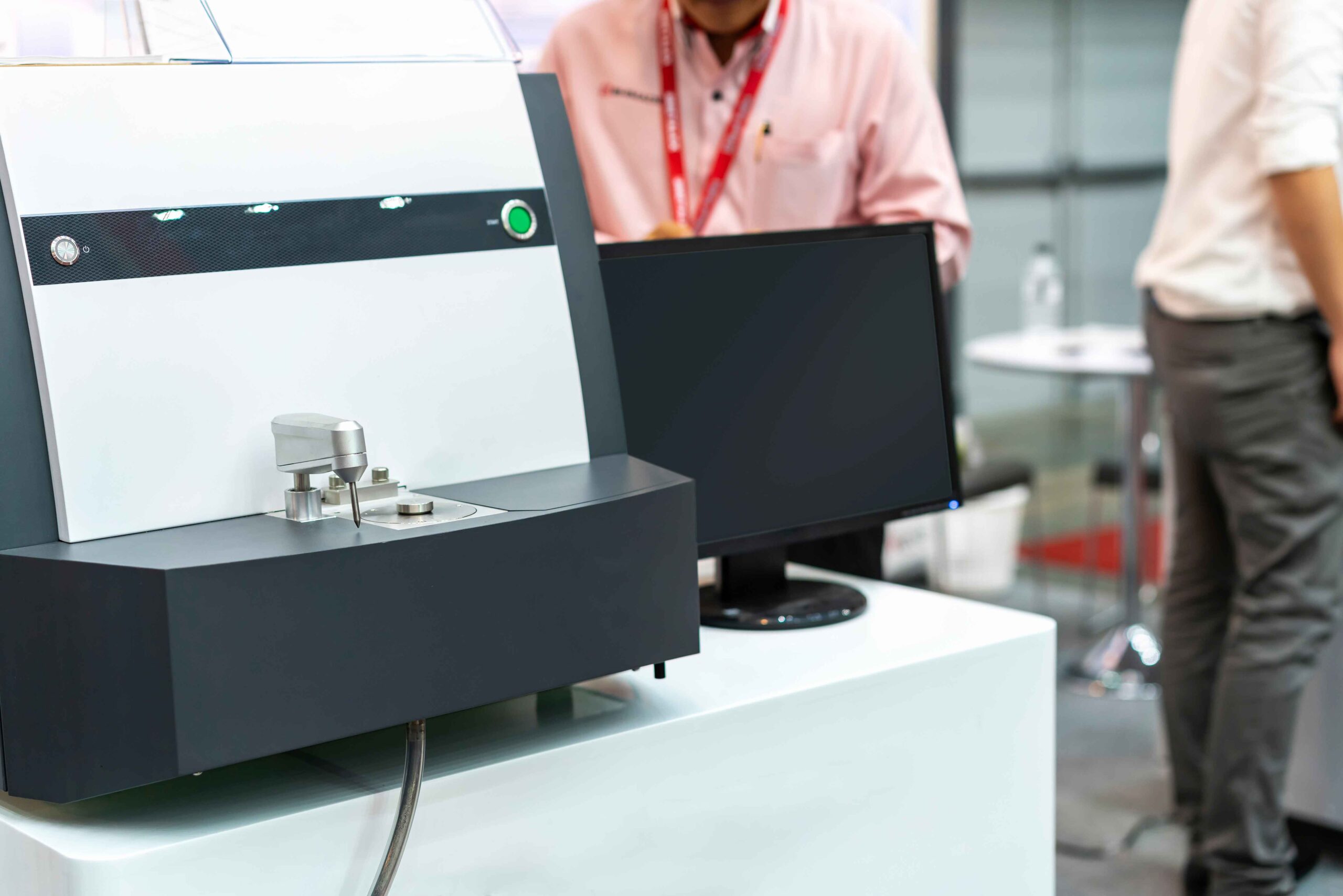

Reverse Engineering – from SGS Ludwig.

Reverse engineering services from SGS Ludwig determines the metallurgical and chemical characteristics of components from a broad range of industries.

A standard reverse engineering evaluation would include chemical testing and identification of AISI, ASTM, or SAE material grade. It can also entail visual and metallographic (microstructure) examination of a component to determine manufacturing method, which includes cast, hot forged, hot or cold rolled, stamped, extruded, or sintered methods. Heat treatment condition of the component can also be determined. Some of the typical conditions vary from annealed, normalized, quenched and tempered, austempered, gas carburized, nitrocarburized, flame hardened, and induction hardened. Mechanical testing of products would include tensile, Charpy impact, and hardness testing to verify any supplied specification requirements.

Our experienced engineers will provide a report to identify the material grade, the method of manufacturing, heat treatment condition, and mechanical properties as necessary based on the findings.