Hardness Testing

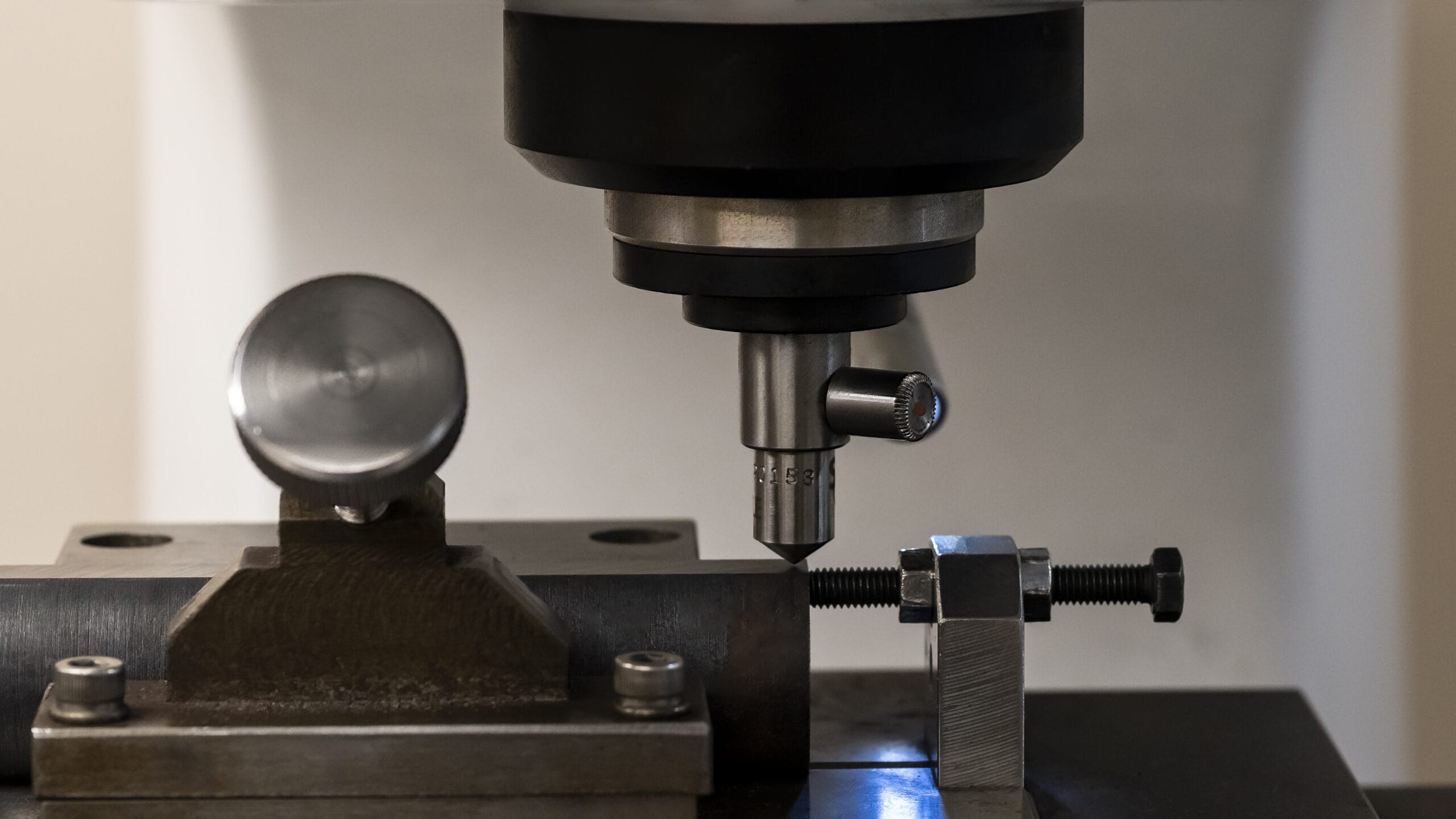

Brinell hardness testing ASTM E10 is among the most common method of hardness testing performed.

Using ASTM E10 as our accredited test specification, Brinell testing is a method of hardness testing using a tungsten carbide ball as the indenter. The indenter is brought into contact with the planar surface of a test specimen and held with a test force for a specified dwell time. The magnitude of the force and the diameter of the ball can vary depending on the material being tested. A typical test (on low alloy steel, for example) uses a 3000kgf force with a 10mm ball.

Brinell Hardness Test Methods

The following is a listing of specifications that are in accordance with our A2LA and ISO accreditation.

- Brinell: 187.5, 500, 750, 3000Kg

- ASTM E10 Standard Test Method for Brinell Hardness of Metallic Materials

Brinell Testing Laboratory

The Brinell hardness of the material is determined by the diameter of the resulting indentation, measured in at least two perpendicular directions and taken as an average. Harder materials yield smaller indentations.

Brinell hardness can provide useful information about the mechanical properties of the material, such as approximate tensile strength, wear resistance, and ductility.

Contact us today to learn more about our hardness testing services.