Failure Analysis

Investigation services examine failures to identify the root cause, define responsibilities and improve future performance.

Failure investigations always start out with the same questions:

- Why did it fail?

- What was the root cause?

- Where is the origin?

- Was there a material deficiency?

All these questions take us on the starting path to the answers. We are your guide and advisor during your investigation, offering you opinions and conclusions based on the facts and conditions we observe.

Your project is given priority and assigned a degreed engineer who will be available throughout your investigation. Approachability and an open level of communication sets our engineers apart from the other labs.

Our team of nine engineers offers expertise in materials evaluation. Real world experience in the manufacturing and fabrication of materials provides the knowledge you need for your investigation project.

Reports are easy to read and written in a ‘conclusion first’ format. This initial summary of the investigation gets to the heart of the matter. discussion the opinion of your project with supporting documentation to follow. Each investigative report includes all testing data, photographs and conclusive statements. We offer GoToMeeting® availability to discuss your reports with other professionals involved in your investigation.

Contact us for more information on our failure analysis services.

Experience

- Failure Analysis

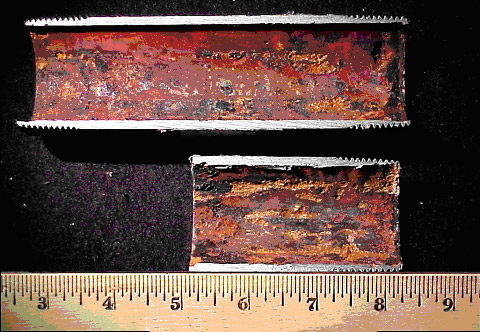

- Corrosion Analysis

- Fracture Analysis

- Fastener Failure Anlaysis

- Steel Failure Analysis

- SEM/EDS Analysis