Mechanical Testing

Surface Roughness Testing from SGS MSi

We perform surface roughness on linear surfaces, our equipment can provide the characteristics of a material’s surface variation per a given standard and specification.

Surface Smoothness Analysis

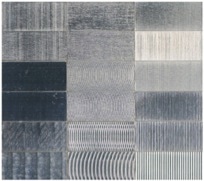

Surface Roughness is a measurement of vertical deviations on the surface of a sample in its ideal form. Depending on the size of these deviations the surface will either be rough or smooth.

A very rough surface will interact differently with other materials due to the coefficient of friction. This may be undesirable when a contact between two parts must be smooth. However, manufacturing a very fine surface is more costly. The application of the parts and their interactions to surface condition will ultimately determine the desired surface roughness.

Contact us today to learn more about our mechanical testing services.

Surface Roughness Test Methods

In accordance with A2LA and ISO accreditation, our lab performs:

- ASME B46.1 Surface Texture (Surface Roughness, Waviness and Lay)

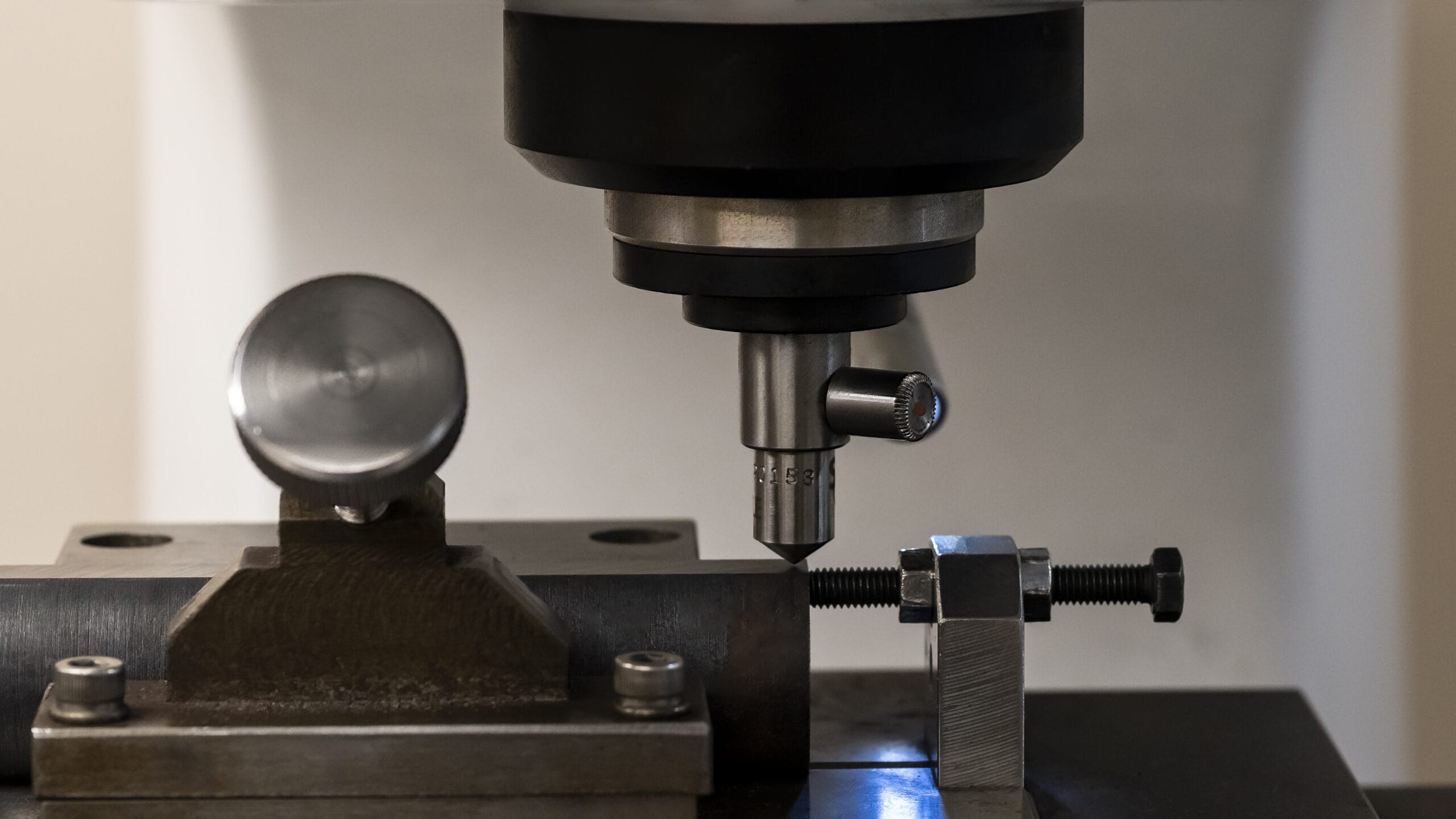

A profilometer is a tool designed to measure the deviations in surface texture. A diamond-tipped stylus runs over the surface of the material reacting with variations in surface texture. When a variation is measured high or low, the profilometer reports the variant data. After scanning, the surface will be given a rating in roughness per the specification requested.

SGS MSi is accredited to perform surface irregularity inspection in accordance with ASME B46; SGS MSi Procedure 590 per our A2LA Certification.