Failure Analysis

Failure analysis from SGS MSi – identify the root cause of metallurgical failures

Our technical experts are highly qualified engineers with industrial skills and problem-solving experience in a variety of failure analysis techniques. Along with highly experienced staff, you’ll benefit from our accredited laboratories equipped with state-of-the-art analytical equipment, unrivaled resources and proven expertise.

We believe in thoughtful reporting practices – you’ll get test reports with rapid and accurate results, that are straightforward and easily read

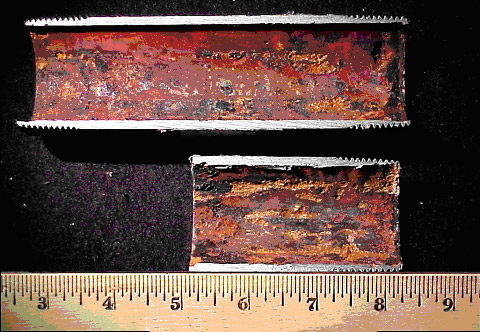

We use extensive, annotated photographs in every report section to assist in relaying visual information to our customers. Our Investigative Summary report style provides all conclusions in the beginning of the report. We offer definitive statements about the failure root cause. If we cannot identify a cause of the failure, we tell you straight out… we do not use the typical engineering speak and terminology that other labs may provide. Many times the supplied samples (or background information) do not contain sufficient artifacts to solve the problem. Our reports do not leave you wondering.

Why use SGS MSi for failure analysis?

SGS MSi is equipped to successfully help our clients in all metallurgical failure analysis situations.

- 40+ On-site employees

- Photographic Department

- Clemex Image Analysis System

- Clemex Stereoscopic Software

- Clemex Microhardness Testing System

- Bar Code Scanning in all Departments

- Air Tubes To Move Samples and Test Data

- 10,000 sq. ft. machine shop

- Metallurgical Laboratory

- Mechanical Testing Department

- Chemical Laboratory – OES & ICP

- 3 Truck Level Docks

- Heat Treating Department

Industry Experience

- Power Generation

- Steel Making

- Foundry

- Forgings

- Aerospace

- Vessels

- Titanium

- Railroad

- Shipbuilding

- Springs

- Automotive

- Farming

- Heat Exchangers

- Medical Implant

- Food Industry Equipment

- Heavy Equipment

- Transportation

- Heat Treating

- Shafts