CWI Testing

CWI Services

SGS MSi’s CWI services consist of tests that help establish welding procedures, procedure qualifications and welder qualifications. Our weld engineers review your process needs and work with our clients to deliver fast accurate test results and certified reports. Each of our reports is formatted to provide clear and easy to read data.

The processes used by our certified weld inspector are in accordance with your materials specification. We can provide a one-stop shop for your inspection needs. Our 10,000 sq/ft machine shop has the capability of extracting specimens from all forms of material.

In the process of inspection includes many tests and examinations. Some of these processes are:

Visual inspection of welds

In this process, we will look at the material to identify any visual indications. A thorough examination of the material in its as received state as well as post-test is observed.

Testing of welds

These tests require the inspection techniques used prior to a metallurgical examination. They are characterized by testing the material in it’s as-welded state to observe any indication or discontinuities present in the weld. These tests allow a better understanding of the integrity of the welds both in developing a weld procedure or a qualification by an individual welder.

Metallurgical testing of welds

The mechanical processes of Tensile Testing, Hardness Testing, Bend Testing and Charpy Impact Testing provide invaluable information about the strength and hardness of the welded material.

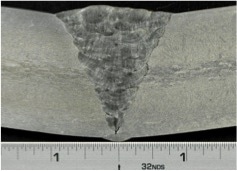

Characterization of the weld profile is another form of internal visual examination. A macroscopic or microscopic interpretation of the weld’s cross-section provides a clear understanding of the integration process between the base metal and weld metal. Photographic documentation is often added to a certification report to show a picture story of the weld.

The chemical composition of welds and weld overlays is essential to the weldability between base and weld material. Determining the elemental composition is a key process to ensure compatibility. After welding has taken place and failure indications appear, the material composition can be identified to understand if correct weld metal was used.

Please contact our sales staff for more information on our CWI services.